Industrial IoT Edge Accelerometer

for Assets Monitoring

Meet us @ SPS-Expo 2025

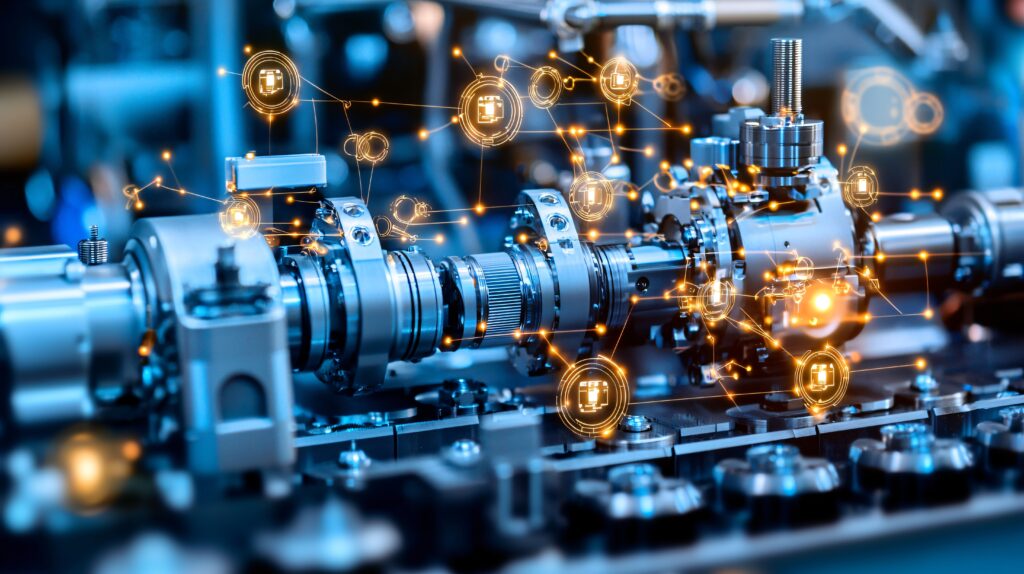

Vibration is one of the earliest signs of failure in industrial equipment. A single defect appearing in spindles, shafts, bearing or gearboxes can degrade process quality, increase power consumption, or even generate a failure causing costly equipment downtime.

Condition Based Monitoring (CbM) systems acting as “machine doctors” can monitor operating modes, predict maintenance operations, and prevent failures. With each mechanical element having its own frequency signature, highly sensitive accelerometers with large bandwidth are needed by modern CbM systems to detect fine-grain defects such as ball or gears issues that cannot be identified by conventional sensors.

Tronics boosts the digital transformation of Condition Based Monitoring systems by bringing an innovative vibration sensor that can be embedded onto any industrial asset and easily connected to existing industrial buses.

Key Features

- MODBUS RTU interface for field bus connection

- Embedded machine health indicators for reduced data transmission

- Programmable digital filters

Key Performances

- 20 kHz bandwidth for detection of ball and gear defects

- Configurable measurement range from 8 to 64 g (configurable)

- Sensitivity 1.4 mg/LSB @ ±8 g (eq. 100 mV/g)

Want to know more?

Visit us on the TDK Booth 334 Hall 10.0 during SPS 2025 in Nuremberg for a live demo of our Industrial IoT Accelerometer or send us a message.

Listen to our lecture on Wednesday 26 at 4 pm (Stage hall 6).