High Performance MEMS Accelerometers & Gyros

Downhole drilling guidance | Survey

Mining and oil and gas exploration and exploitation tools require highly robust inertial sensors able to provide precise data under harsh operating conditions. MEMS technologies provide a reliable, low-SWaP and cost-effective alternative to bulky and expensive analog quartz accelerometers and FOG (Fiber Optic Gyros), demonstrating challenging performances at a fraction of their price, size and power consumption.

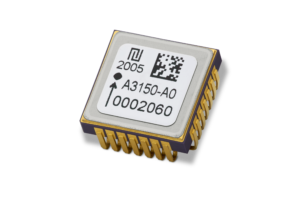

Discover AXO®315

High performance ±14 g digital accelerometer

Discover GYPRO®4300

High stability ±300 °/s digital gyroscope

Survey and drilling: digital inertial sensors for precise guidance

Miniature MEMS accelerometers and gyros can be combined into a compact Inertial Measurement Unit (IMU) that fits into a drilling or survey tube with a constrained diameter, with no performance compromise on the measurement axis.

For precise guidance and orientation of survey and drilling instruments, Tronics provides high performance digital MEMS accelerometers and gyros housed in a miniature hermetic and ceramic SMD package.

Tronics AXO®315 ±14 g accelerometer demonstrates a low bias residual error of 0.5 mg and a 1 mg composite bias repeatability over its temperature range. It is ideally complemented by GYPRO®4300, high stability 300 °/s rate gyro that exhibits an ARW of 0.07 °/√h and a bias instability of 0.4 °/h.

Their fully digital architecture with 24-bit SPI output removes the need for discrete components on the PCB and drastically simplifies their integration at system-level.

High vibration rejection and reliability

To cope with the severe environmental challenges of downhole drilling, AXO®315 and GYPRO®4300 are designed with a closed-loop architecture that ensures highly linear response and excellent vibration rectification error for precise tool orientation and guidance under high vibrations and shocks.

Thanks to their solid-state architecture that reduces the number of internal components and system complexity, Tronics’ MEMS inertial sensors demonstrate a MTBF higher than 1 000 000 hours, more than 10 times better than incumbent quartz accelerometers and Fiber Optic Gyros.

Let's talk about your next drilling or survey project!

© Tronics 2023

TDK Logo is a trademark or registered trademark of TDK Corporation