Industrial IoT Edge Accelerometer

for Process and Asset Monitoring

Industrial IoT Edge Accelerometer

for Process and Asset Monitoring

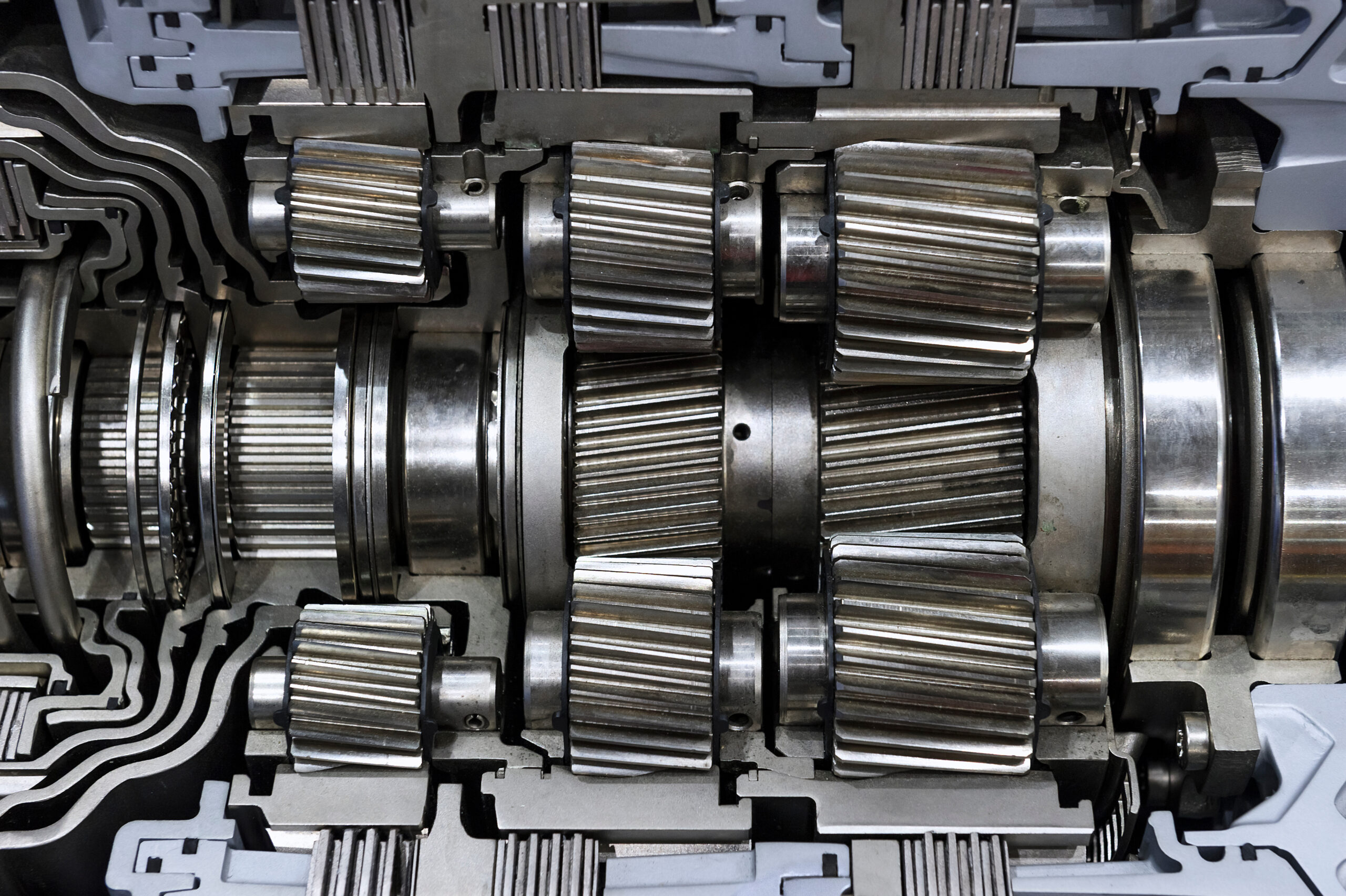

Spindles, shafts, bearings, and gearboxes are the key elements of industrial equipment such as motors, pumps, compressors, production tools and wind turbines. Any issue of these parts could create unbalance or misalignment, reduce process quality, increase power consumption, or generate a failure up to equipment downtime. Condition Based Monitoring (CbM) systems acting as a “machine doctors” are deployed to monitor operating mode, predict maintenance, and prevent equipment failure. As vibration is one of the earliest signs of failure of mechanical elements having their own frequency signature, CbM systems must rely on highly sensitive and large frequency bandwidth accelerometers acting as the key vibration stethoscope.

MEMS based digital accelerometer offers extended capabilities

High frequency for mechanical issue detection

MEMS accelerometers compete with performances of incumbent piezoelectric accelerometers in terms of large bandwidth from 0.5 Hz to 20 kHz, range up to ±64g, sensitivity and noise which make them ideal for vibration recording and any mechanical issue detection like ball or gear issue.

Digital output rate up to 50 kHz of MEMS accelerometers enables accurate computation of Fast Fourier Transformation.

Robust digital CAN or MODBUS RTU interface to ease integration

The integration of vibration sensors onto equipment requires cables, gateway for data communication. The MEMS accelerometer developed by Tronics performs a native digital transformation of the vibration signal. Raw data are transferred under proven, reliable and secure CAN or MODBUS RTU communication protocol, making accelerometers easily connected on a daisy chain manner to single cable industrial field bus.

Embedded machine health indicators for reduced data transmission

The transmission of acceleration and velocity raw data requires up to 1 Mb/s data rate for an accelerometer with 20 kHz bandwidth.

Dynamic range and frequency filters can be adapted to the machine use-case. Indicators like Peak, peak-peak, RMS, Crest factor are locally computed with processing at the edge, resulting in a data transmission rate reduced from 1 Mbit/s (raw data) down to Bytes/hour (indicators).

Industrial IoT Edge accelerometer to boost CbM digital transformation

Relying on Tronics MEMS edge IoT accelerometer embedded onto any asset and easily connected to field bus, CbM players will be allowed to reduce their need of expensive gateway, cables and labor. They can also envision a complete digital transformation, starting at the bottom of the ladder with the digitalization of the vibration emitted by rotating equipment, perform edge computation of key indicators the use case and transmit them in a reduced data rate focused on machine health monitoring.

Applications

Motors

Pumps

Wind turbine

Shaft

Gearing

Bearing