Inertial foundry solutions for custom MEMS devices

At Tronics we have more than 20 years’ experience in manufacturing high performance inertial MEMS devices built on thick SOI wafers and reliably encapsulated in hermetic and vacuum wafer level packaging. We offer a library of proven technology blocks, acquired through extensive development and qualification efforts and consolidated by years of mass production under SPC, aerospace EN 9100 certified quality system (based on IATF 16949 automotive standard).

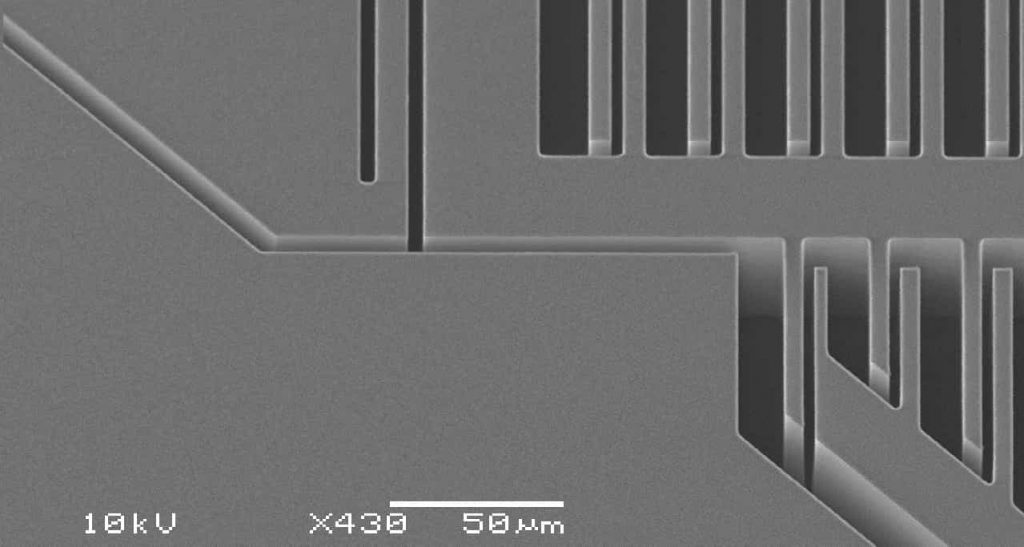

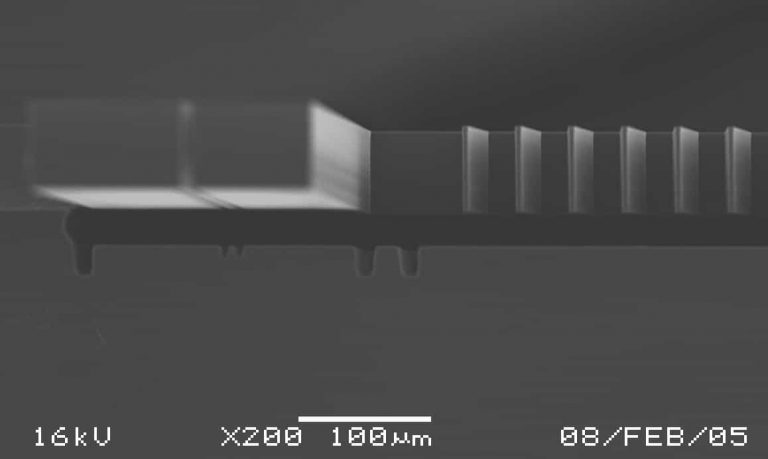

Pioneer of MEMS on thick SOI over cavity

We were pioneer in the production of MEMS with DRIE on thick SOI. Building on the foundation of a surface micromachining technology on thick SOI over cavity wafers developed at CEA-Leti in the 1990s for seismic geophones, and augmented by 20 years production of accelerometers and gyros, we are a recognized technology leader for inertial MEMS on SOI.

Our core technology of High Aspect Ratio Micromachining by DRIE on thick SOI (from 40µm to 100µm) on cavity (also called C-SOI) enables the stiction-free release of electrostatic comb-driven spring-mass and plates capacitive structures for single-axis and multi-axis inertial MEMS devices such as vibration sensors, linear and resonating accelerometers, and vibrating gyros in open or closed-loop configuration.

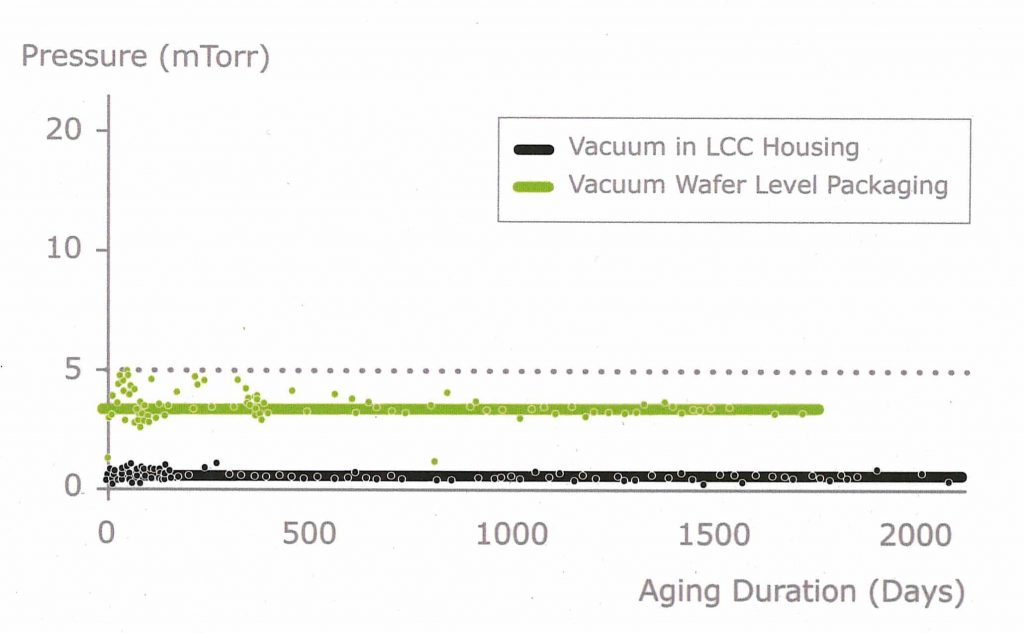

Expert in hermetic and high vacuum Wafer Level Packaging

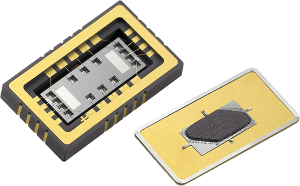

Since our foundation we have always put an emphasis on the protection of our microstructures by wafer level packaging (WLP) to ease customers handling and assembly and ensure the long term reliability of the devices we manufacture. We propose a set of hermetic and vacuum wafer level packaging (VWLP) with metal routing on cap and lateral or vertical vias interconnection solutions that ease the manufacturing and the integration of the MEMS die at the sensor level by our customers.

For resonating and vibrating structures, we offer high vacuum wafer level packaging solutions with in-house deposited integrated getter that ensure long term stable and reliable vacuum <10mTorr. Those solutions have been built on a robust foundation and expertise in high vacuum assembly and packaging of MEMS in ceramic packaging with getter.

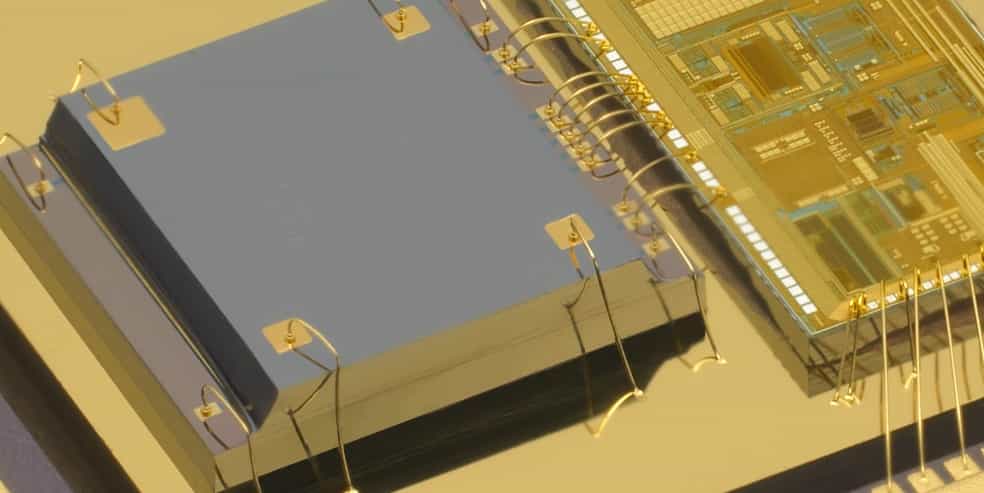

Hermetic assembly and high vacuum packaging

Our in-house assembly and packaging capabilities and competencies enable us to efficiently manage our supply chains to deliver packaged and tested components to our customers. We master soldering, brazing and gluing die attach, side-by-side or stack-die wire-bonding assembly, and hermetic or high vacuum <1mTorr encapsulation in ceramic packages with getter. We put a particular care in low stress assembly and thermal decoupling in order to ensure the best possible performance for our customers.