True to its reputation as a pioneer in special processes, Tronics is capitalizing on the growing number of submicronic MEMS devices opportunities to expand its equipment and process base.

VIEW ONLINE: Link to PRWeb

True to its reputation as a pioneer in special processes, Tronics is capitalizing on the growing number of submicronic MEMS devices opportunities to expand its equipment and process base.

Tronics has been manufacturing MEMS for 15 years with an emphasis on SOI, WLP, and has always specialized in manufacturing processes requiring innovation and creativity.

Over the last 2 years, Tronics acquired advanced equipment and allocated significant resources to the development of submicron MEMS processes, which combine traditional MEMS structures and advanced Nanotechnology parts. There are a growing number of opportunities for submicronic MEMS devices in optical applications, but also in inertial and microfluidics applications.

Tronics acquired a 0.25 i-line stepper to address some of these opportunities. In the world of MEMS, this is high resolution. The stepper allows the patterning of the very small geometries necessary for many applications, such as piezoresistive inertial MEMS based on silicon nano-wires (M&NEMS), or micro mirrors for telecommunication applications. This machine is also needed to manufacture moving structures requiring very tight alignment.

Tronics also acquired equipment for nanoimprint lithography (NIL). This technique allows the creation of structures with superior resolution, as small as 50 nanometers, by embossing a resist with a stamp. This technology is cost effective for patterning large areas, once the processes have been properly developed and validated. Tronics was one of the first European companies to bring NIL to industrial production, and is now using nanoimprint to define high-density structures on both silicon and glass substrates.

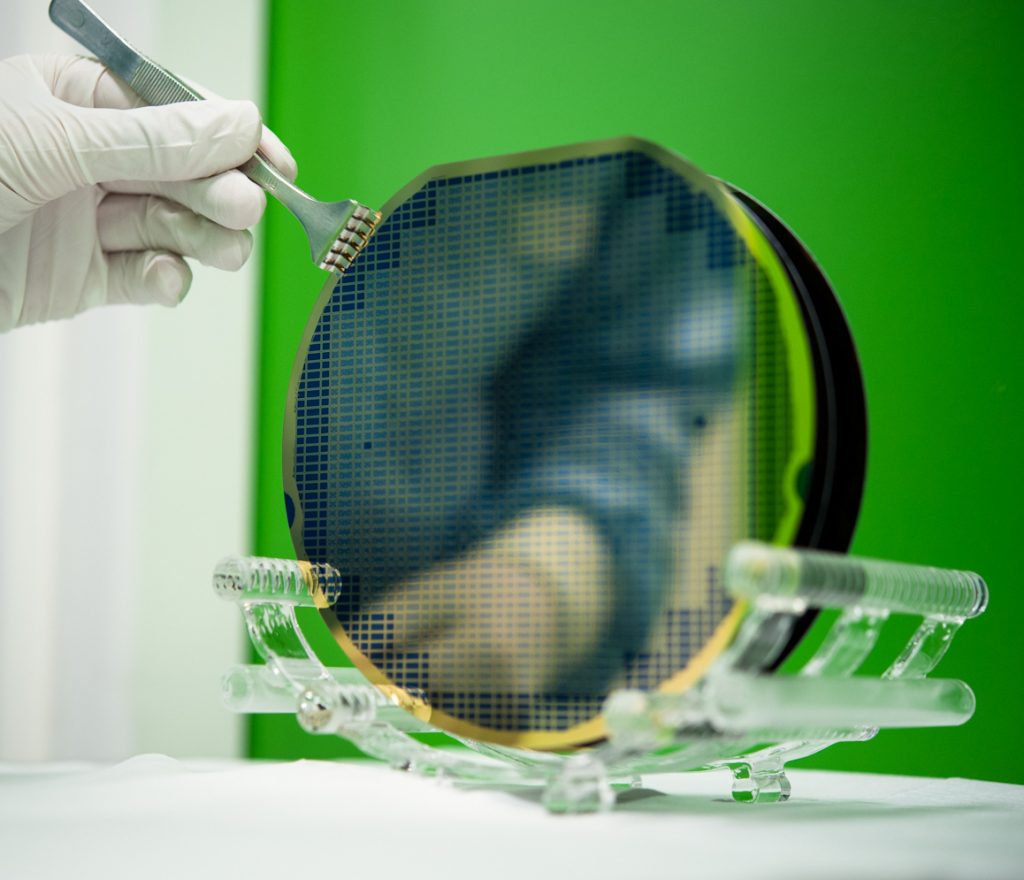

With a total investment in excess of 2 million Euros in this field over the last 18 months, Tronics has clearly demonstrated its commitment to becoming a leader in the submicronic MEMS business. The new equipment is fully operational at Tronics and is being used for product deliveries to customers. More than ten thousand wafers have already been processed and delivered.

The range of applications requiring such tight alignment or submicronic patterns is broad and growing. Some examples are submicronic optical gratings , spectrometers, fluidic filters, piezo-resistive inertial sensors based on silicon nano-wires, micromirrors, gas sensors based on resonant silicon nano-cantilivers, and there are many others.

Pascal Langlois, CEO of the Tronics group said: ”Tronics is committed to further developing the know-how required to address these opportunities, and to expanding its equipment and process portfolio. Tronics will continue to build on its solid MEMS engineering background and its ability to solve difficult MEMS manufacturing challenges, and plans to remain a leader in specialty MEMS processes.”

Tronics will continue to build on its solid MEMS engineering background and plans to remain a leader in specialty MEMS processes.